Chemical recycling is a nascent industry, having really only reached commercialization in the last five years or so, but its reach and relevance are quickly expanding, according to participants at the inaugural Advanced Recycling Summit in Chicago on Tuesday and Wednesday.

Session speakers highlighted how many details surrounding the early-stage industry still have to be worked out, including terminology: It might be called “chemical recycling,” “advanced recycling” or “molecular recycling,” depending on who you ask.

“There's been sort of a renaissance in chemical recycling, or advanced recycling, over the last, I would say, six or seven years,” said Anne Johnson, principal and vice president of global corporate sustainability at consultancy RRS, noting she started studying the field in 1998. “I think we have to be clear in this message ... about conserving resources, just very basic ... get back to why do we actually recycle [and] why is this an endeavor that’s important?”

Chemical recycling has certain advantages over mechanical, such as not struggling with mixed material layers or dark colors, according to Benjamin Trent, managing consultant at Smithers, the consulting group that hosted the conference. Numerous speakers extolled chemical recycling’s ability to break down hard-to-recycle plastics for reuse rather than disposing them and tapping into raw material supplies such as petroleum.

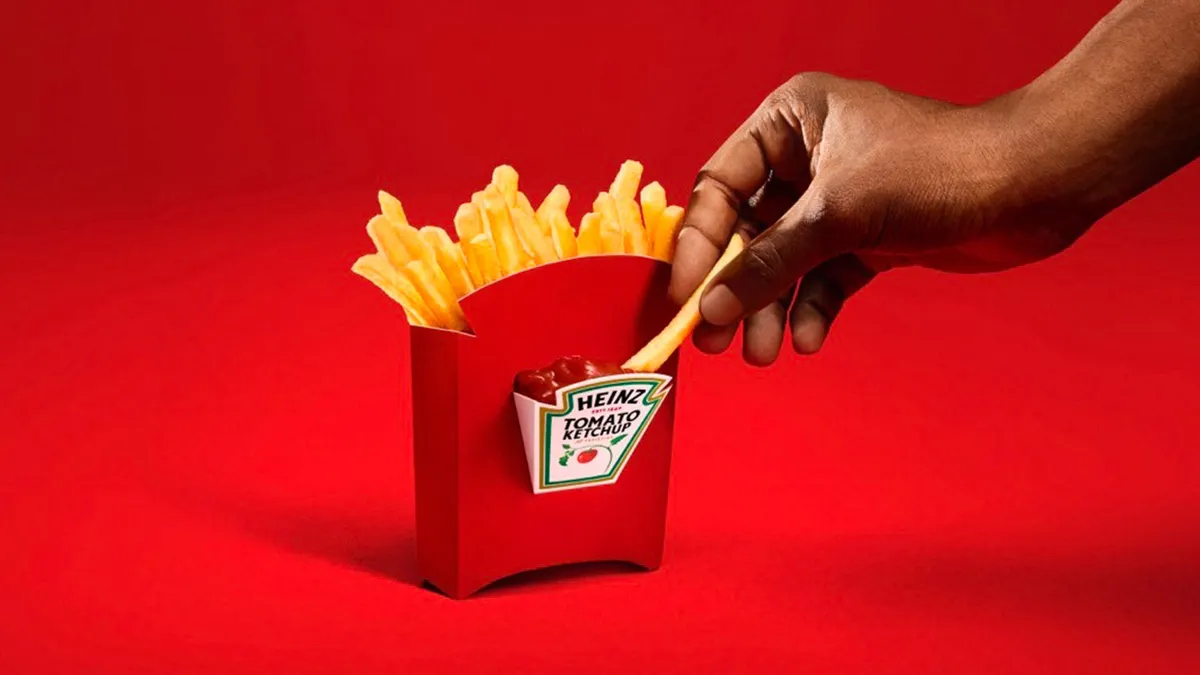

“This is a method to take plastics that currently are not being recycled today and make virgin quality recycled content ... [including] food-grade recycled content that wouldn’t otherwise be available,” said Robert Flores, vice president of sustainability at Berry Global. “When you look at the mechanical recycling stream, it is very difficult for us to get back to a food grade. So a couple years ago when I started hearing about this new pyrolysis or chemical recycling or advanced recycling, I got really excited.”

Entities including Amcor, Dow, the Flexible Packaging Association and the U.S. Plastics Pact are among those increasingly exploring advanced recycling as a way to capture and reuse more plastics that otherwise could become waste in the environment. But the industry faces pushback from the likes of environmental groups, government officials and recycling groups who don’t want the practice designated as a form of recycling or plastics management. Conference speakers noted the need for the discrete industry players to work together to develop messaging that effectively communicates to potential partners and the public how advanced recycling is a value-add prospect.

“We've got a lot of smart people in the industry ... But what we tend to do, collectively, is confuse average people,” said Jeremy DeBenedictis, president of chemical recycler Alterra Energy. “We're burying oil every day when we make a choice to throw [out] our multi-layered plastic packaging,” to the tune of 2 million barrels of crude oil daily. “Let’s just replace fossil material. We can do that by figuring out how to get more of the carbon and more of the plastics back from the environment” and into chemical recycling systems, he said.

Participants discussed how chemical recycling should be considered complementary to — not a replacement for — other plastics management strategies.

“I wouldn't want it to get misconstrued that this is somehow pulling [material] from mechanical recycling and we're not net-increasing our ability to recycle more plastic,” said Brad Price, managing director of technical due diligence at New Energy Risk. “I think that needs to be the headline story here, is that all of this together is going to increase our ability to recycle waste plastic.”

Even operators with businesses that center on mechanical recycling, like WM, view chemical recycling as a future opportunity rather than competition.

“Advanced recycling is another tool in the toolbox,” said Shannon Crawford, WM's director of recycling and environmental policy. “We do support it in the ... same way that we support other mechanical recycling as well — we don’t have any sort of hierarchy.”

Life cycle assessments, which consider a product or service’s impact throughout the entire supply chain, are a way to quantify chemical recycling’s benefits, according to Christoph Koffler, technical director of sustainability consulting at Sphera Solutions.

“As a converter, we're working through the supply chain to really connect the different linkages and get ahead of all those key questions on life cycle assessment,” Flores said. “We have to understand all those different asks and then communicate those benefits” of chemical recycling.

One group of panelists discussed how commercial chemical recycling’s newness has left supply chain gaps. For example, panelists cited challenges with adding infrastructure due to financing, with DeBenedictis suggesting companies installing the technologies can’t foot the entire bill. Speakers also noted potential issues with feedstock availability due to material collection barriers — especially for residential recycling — or possible competition for material with mechanical recycling.

“At some point, we're probably going to need to have the conversation on which plastic probably goes where,” Price said. “But I think at this stage, the thing we need to harp on is that this is going to be something that dramatically can increase our ability to recycle waste. All the other things we can sort out later.”

Despite the challenges, industry players encouraged each other to keep trying because innovative sectors take time to build.

“You’ve got to stick it out. You’ve got to stay in your jobs. You’ve got to do it for a decade,” DeBenedictis said. “You’re making a difference, and that’s what matters at the end of the day.”