Ball is seeking to balance sustainability pressures with aerosol customers’ marketing demands, pitching one of its printing technologies as a solution.

As aerosol customers seek to accelerate on their net-zero goals, sustainability remains the biggest trend in the business, according to Victoria Marletta, commercial vice president for aerosol packaging at Ball.

Like other packaging companies pursuing more sustainable products, aluminum specialist Ball has worked to lightweight its offerings. But that pursuit has led to fewer unique shapes, said Marletta.

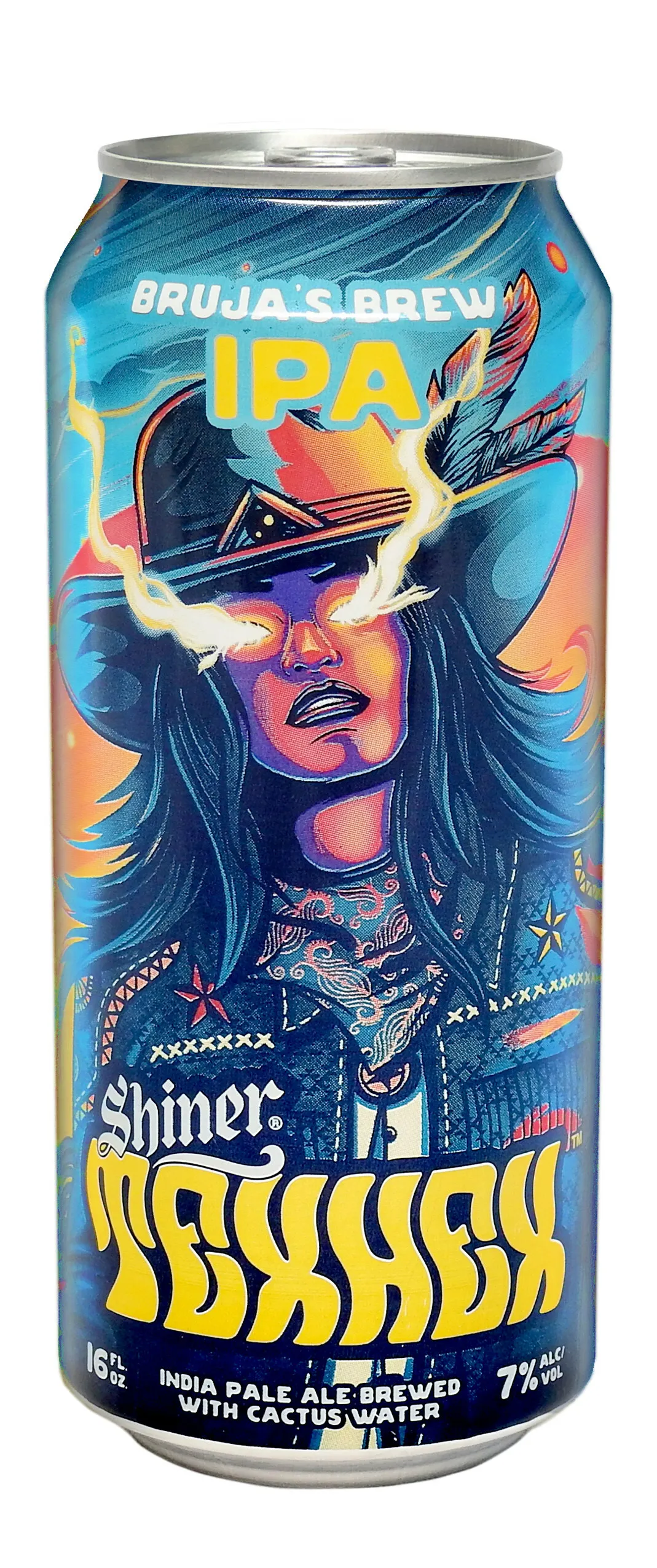

In light of that shift, the company believes that differentiated printed designs are of heightened importance to help aerosol cans pop visually. “We have more and more of a need of creating cans that will stand out on the shelf,” Marletta said.

Ball introduced its high-definition printing technology, which it calls Eyeris, more than 15 years ago, and has mostly used it in the company’s larger beverage business. In more recent years, Ball optimized the “photo-realistic” technology for the growing aerosol business, which sells impact extruded aerosol cans as well as refillable and reusable bottles and saw a 12% increase in product shipments in 2022. The company recently put out a report on the offering and is now more broadly commercializing Eyeris to aerosol customers, according to a spokesperson.

The company said it planned to install five new aerosol manufacturing lines globally in 2023. Former CFO Scott Morrison said earlier this year that volumes were growing after being impacted during the COVID-19 pandemic, in the typical personal care space as well as in water.

“Throughout the last few years, we have been perfecting the technology for aerosol cans,” said Marletta — getting it to a place where in depicting ingredients or fragrances, for example, it can accurately present colors and textures. “We believe that [with this technology], we can achieve a much more impactful product.”

Ball’s analysis of the printing method’s effect on overall sustainability metrics suggests neutral impact, Marletta said, and the printing does not affect aluminum’s recyclability.

The aerosol packaging division accounted for about 11% of Ball’s overall scope 1 greenhouse gas emissions in 2022 and about 4% of its scope 2 emissions. Ball now uses a proprietary lightweight alloy it calls ReAl in more than half of its aerosol cans, which the company says results in cans that are 30% lighter than “a standard aluminum aerosol container.” Cans are becoming more uniform and standardized, and less shaped, increasing the potential benefit of more detailed or higher-definition branding, Marletta said.

The lightweighting ambitions continue; by 2030, Ball is working to launch the next iteration of that alloy with 75% recycled content. In 2022, its Re:gen products — the name for its newer, lower-carbon aerosol cans — were made with 50% recycled content.

Marletta said Ball has seen interest from customers focused on natural ingredients, for example, that want to communicate the benefits of those ingredients to the consumer through packaging. The approach could be especially relevant for products with images that appeal to the senses, said Marletta. “Think about flowers, or foods, or anything that really wants to evoke a sensation in a consumer.”

Ball says it sees further growth opportunities in aerosol as demand rises for sustainable personal care products, to the tune of an additional $15 million in 2024 from the natural beauty market. “Ball Aerosol has the opportunity to capture larger shares of the personal care packaging market, particularly the natural beauty market which focuses on sustainable practices,” the company outlined in its 2022 CDP report.