Emerald Packaging is marking a transition in the family-owned business as it also presses forward on incorporating recycled content into its products.

James (Jim) Kelly, 66, is a one-third owner of the flexible packaging business that his father co-founded in 1963. He’s stepping down as executive vice president after 41 years at Emerald Packaging.

Prior to joining the family business, Jim Kelly worked in sales at Procter & Gamble. His two siblings also each have one-third ownership, with younger brother Kevin Kelly still serving as CEO.

Not a lot will change in day-to-day operations at the California-based produce packaging specialist, Jim Kelly said. “We have young, smart, really good people who have been coming up through the ranks for years,” he said. “So I think to an outside eye, it will be business as usual.”

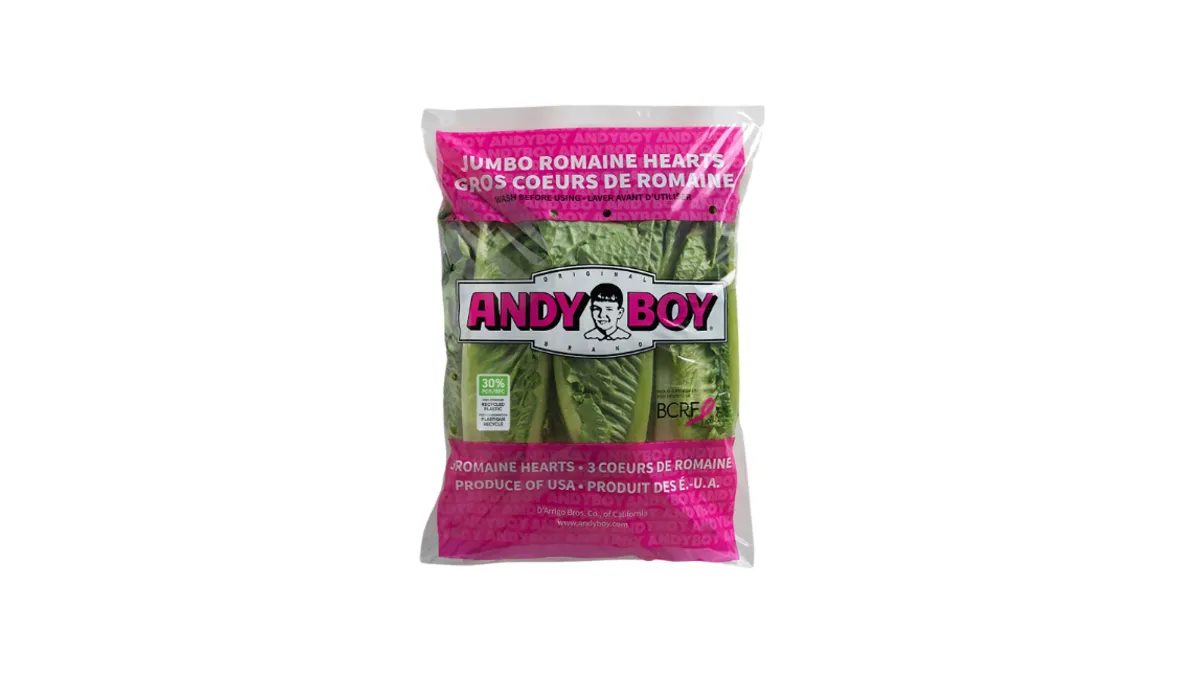

The privately held company reports sales of $90 million and lists produce players Dole, Taylor Farms and D’Arrigo Brothers among its customers. Emerald typically has between 250 and 275 employees, with 30 in the office and the rest in the factory, he said. Emerald credits Jim with helping to drive packaging innovation and sales for fresh-cut produce.

He recounted major produce market innovations in the 1980s and 1990s, including the introduction of baby carrots and packaged salad, calling them “radical revolutions in terms of convenience for the consumer.” Kelly explained how the company worked with food scientists to formulate a range of packages with different films, thicknesses, micro-perforations and other features.

“The challenge for Emerald in those days was to develop packaging that would breathe at the same rate as whatever was being packaged,” he said. “The respiration rate of 5 pounds of kale is different from the respiration rate of 2 pounds of kale, which is different from 1 pound of carrots, which is different from 3 pounds of romaine.”

Unlike more diversified packaging companies, “99% of what we do is produce, so we really know the product line top to bottom. And that's worked out for our customers in the long run,” he said.

Looking ahead

Emerald wants to grow organically and potentially expand nationwide, in addition to being outspoken on plastics issues, said CEO Kevin Kelly.

PCR is “the future for Emerald Packaging and undoubtedly the future for the industry,” said Jim Kelly, because it balances the need to address plastics’ harms while still giving the produce industry what it needs to preserve a product over long time spans and distances. Balancing supply and demand for PCR will be a key challenge going forward, he said.

Thus far, cost has been a barrier. “Retailers and customers are hardwired not to want any price increases ever,” Jim Kelly said. “And so we're butting up against that, but we're going to do it.” Emerald currently absorbs cost differential when incorporating PCR, according to the company. Executives believe supporting the market is essential for it to flourish and that securing contracts now will pay off when there’s a crush of demand around 2025.

Emerald, an Ellen MacArthur Foundation signatory, is also encouraging customers to get involved more in regulatory affairs so legislators recognize how produce packaging ought to be differentiated from certain other types of packaging.

The family’s next generation will have the option to decide in the coming years whether operations will continue to be family-run. Kevin Kelly also noted increased private equity presence in the sector. “The flexible packaging industry more and more is the playground of private equity,” he said. “Most of the owner-operators have been bought up by private equity companies.”

But he still thinks it’s early to judge private equity’s success in this market and whether it’s a good fit for three- to five-year demands of private equity. “We’re very much hostage to raw material prices; private equity is not so used to that. So we're going to have to see how those companies do.”