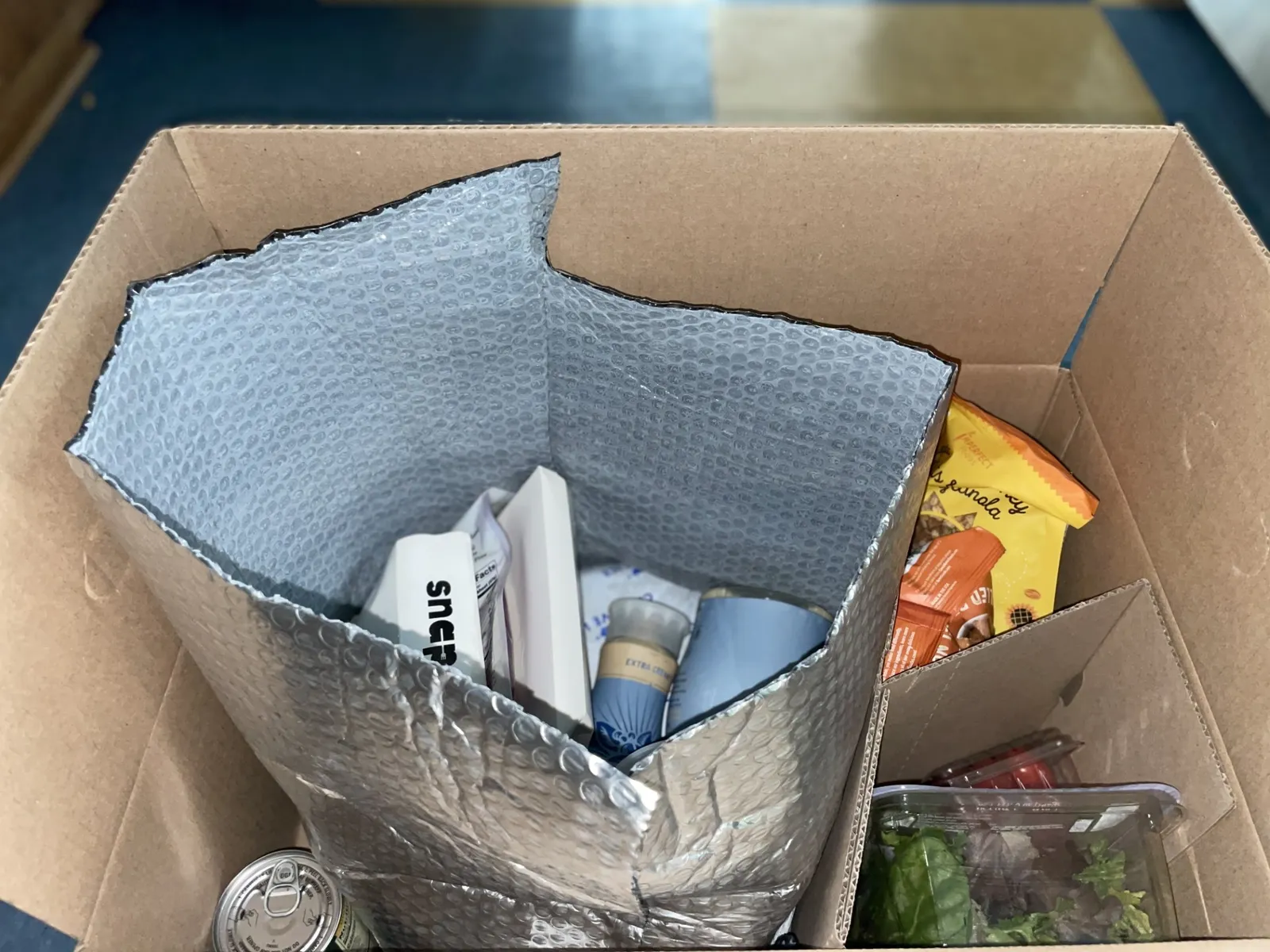

Getting fresh food items safely to consumers takes careful planning and the right packaging. Multiple e-commerce grocery and meal-kit providers are using personalized packaging and reverse logistics for recycling in an effort to balance customer needs with sustainability commitments.

Grocery e-commerce grew during the COVID-19 pandemic as customers prioritized safety and convenience, and market research generally indicates that growth will continue. Companies such as HelloFresh, Misfits Market and Dispatch Goods are among those experimenting with packaging innovations as the sector develops.

Packaging optimization at HelloFresh

HelloFresh optimizes packaging such as insulation and ice packs based on seasonality and geographic location. Using thermal and shipping models, it forecasts the number of boxes and liners needed per temperature range and region.

"For example, a customer in Michigan, who doesn’t live in the same environment as a customer in southern Arizona, would receive different packaging," said Katie Homa, senior manager of sustainability, via email. "Rather than send the same insulation to both — which would be wasteful — we optimize the insulation for the climate zone the box is destined for."

A typical packaging configuration includes a liner, ice pack and a separator for the ice packs and frozen proteins at the bottom of the box. But in some cases, the company has removed liners and replaced them with a protein pouch that contains an ice pack and frozen proteins. Last year, during the first two weeks of January, the company shipped 2 million boxes without liners.

"This configuration allows HelloFresh to forgo liners seasonally when not necessary while still protecting the meal kit bags from direct contact with the frozen items in the box," Homa said.

In international markets, HelloFresh’s Paper Pouch is made from recycled paper and uses air cushions for insulation. It was developed in collaboration with students from Lund University in Sweden and an unnamed German company. Newly developed packaging solutions are tested in HelloFresh’s Packaging Labs — located in England and New Jersey — where teams look at heat insulation, water absorption and structural resistance.

Reuse at Misfits Market

At Misfits Market, which acquired Imperfect Foods last year, the team also uses an algorithm to minimize packaging while maintaining food integrity. Through this rightsizing approach, the company has reduced the average number of boxes per order from 1.2 to 1.1.

“[It] doesn’t sound like a lot, but when you’re sending hundreds of thousands of orders every year, it ends up making a difference,” said Rose Hartley, head of sustainability at Misfits Market.

Hartley and her team also wanted to find a way to get some of the packaging sent to customers back into circulation. This includes materials the company sends to consumers that “don’t have great end-of-life options” for recycling or reuse. “A lot of the impetus was to create this solution for our customers, because they were asking for it,” she said.

Via a partnership with Watershed, a platform for measuring carbon emissions, the company has calculated its carbon footprint to accurately assess the impact of these efforts. It reduced by 51% the greenhouse gas emissions that would otherwise be produced by manufacturing additional packaging materials, and it reduced packaging weight by 63%.

The key materials that Misfits Market focuses on collecting are the gel packs, silver LDPE insulated liners and LDPE egg carton liners. The team that delivers customers’ orders can take back packaging items while making a new delivery. The company implemented the collections process in December 2020 and rolled it out to Imperfect Foods customers in June 2021. Logistically, it’s a challenging process shift.

“We are forcing a linear system to close the loop,” Hartley said. “It’s not easy.”

She explained that it was a big lift for the drivers, especially at first. The company limits the amount of packaging that can be collected from each customer per visit to make sure the delivery van has ample space. To date, the delivery team has collected more than 9.3 million pounds of packaging.

The insulated liners and egg cartons are aggregated and sent in large quantities to Recyclops, a recycling service provider. “They’re broken down into pellets that can be used for recycled plastic products,” Hartley said.

Meanwhile, the company works with several different partners, including Dispatch Goods, near each of its fulfillment centers to get the gel packs cleaned and ready for reuse. The system is decreasing the company’s use of virgin materials.

“Not everyone has curbside recycling, period,” Hartley said. “I see our packaging return program as a first step in our extended producer responsibility.”

Dispatch Goods founder and CEO Lindsey Hoell describes her company as a “circular logistics platform,” which makes revenue from helping brands reclaim or reuse certain elements of their packaging. Currently, the company has processing centers on the East and West Coasts that handle material, which is often collected via reverse logistics systems, and clean it through what Hoell calls “tech-enabled dishwashing laundromats.”

“Cold chain packaging is generally really durable because it has to maintain temperature and it has to often travel long distances,” Hoell said. This makes it ideal for reuse, and Dispatch Goods works with brands to help them make the switch to more durable packaging. Gel packs go through pressure testing and quality assurance before getting sent back to partners in the meal kit and grocery delivery sector. Dispatch Goods typically rejects 10-20% of what is returned in the process.

“We do have custom operating procedures for all the brands that we work with,” Hoell said. “Whatever we send back to the brand is usable.” What this means in practice varies depending on the company: Some brands are willing to accept cosmetic imperfections on the items that Dispatch Goods returns to them, whereas others want the items to look like new. When onboarding a partner, the company reviews the specific protocols.

In Hoell’s experience, the system is something that consumers find valuable. “What we have learned is that customers want to send back the packaging, either because they care about the environment, or just they feel frustrated they have to deal with it.”