The once-ubiquitous plastic container of laundry detergent is starting to be replaced as more brands adapt to alternatives that involve bio-based materials, refillable containers and other options.

The trend comes as an increasing number of major CPG companies work to lower carbon emissions, create more recyclable packaging and reduce plastic use in line with their sustainability pledges. Major players in the laundry space such as P&G and Clorox have made at least 75% of their packaging recyclable or reusable, according to the companies’ latest data reports.

“Our member companies not only have made those pledges, but they're actively achieving those goals,” said John Hewitt, vice president of packaging and sustainability at the Consumer Brands Association, which counts the above companies as members.

HDPE or PET laundry detergent bottles tend to be widely recyclable and increasingly feature recycled content, but interest is also rising in other packaging formats including fiber boxes, metal containers or options made from emerging materials.

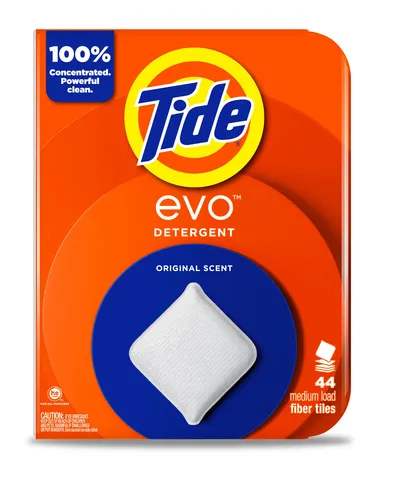

This past week, P&G debuted its Tide evo product: “fiber tiles” that the company says layer soap “without unnecessary liquid and fillers.” P&G says this design was years in the making and is “unlike anything offered in laundry today.” The product comes in a recyclable paper box and will initially be available in the Colorado market before expanding nationally later in the year.

In another example, U.K.-based seaweed packaging company Notpla has partnered with detergent maker Mack to create one of the first seaweed-packaged laundry sachets, which launched last July. The plant-based film dissolves in water and biodegrades. Given its seaweed material, the company says it does not leave behind microplastic waste, a criticism that some make against certain pods and sheets.

“We have found that it has incredible properties that can provide the same efficiency as plastic, but without the cost of it,” said Chiara Ferrari, marketing and content creation associate at Notpla.

When discussing less plastic-intensive laundry packaging, experts say it’s also important to recognize source reduction as an important option. This can come in the form of pods, powders or other formats that don’t rely on standard detergent bottles. In some cases these materials still come in plastic packaging, though it may be smaller.

“The benefit of source reduction is immediate,” Hewitt said. “You get less packaging.”

Another growing market is detergent sheets, which significantly reduce the need for packaging because they can often come in small fiber boxes. Sheets also weigh less than pods, so it can take less energy to produce and transport them.

“The packaging is actually what makes up a majority of the total carbon emissions of a product,“ said Greg Genco, founder and CEO at Generation Conscious, a company that provides liquidless laundry sheets to college institutions via refill stations.

Canadian company Tru Earth’s dissolvable laundry sheets, known as “Eco-Strips,” weigh less than three grams each and come in plastic-free recyclable packaging that is smaller than a smartphone. Anita Spiller, the company’s vice president of ESG, said that Tru Earth’s alternative packaging prevented 160 million plastic jugs from entering “oceans and landfills” last year. She emphasized that liquid-free laundry products “save space not only in your cabinets, but also in the supply chain.”

Many newer laundry products contain polyvinyl alcohol, or PVA, which has become a staple ingredient due to its film-forming properties and dissolvability. Certain detergent brands, including Blueland, say PVA contains microplastics that pollute the waterways. The American Cleaning Institute has said that environmental groups are spreading false information about PVA as part of a marketing campaign led by a company that intends to prevent others from using the chemical. It also notes that PVA aligns with the U.S. EPA’s Safer Choice standards, which assesses environmental and human health factors.

Last year, Blueland petitioned for the EPA to remove PVA from its Safer Choice list, which the agency denied. Recently, New York City council members introduced a bill backed by Blueland that could ban local sales of certain laundry pods and sheets.

While PVA is found in many laundry products, it’s most present in pods, such as products from Tide and Dropps. Single-use laundry pods rose to popularity in the 2010s due to their convenient and lightweight nature.

“A lot of these alternatives have a percentage of sustainable ingredients within them, but they still contain PVA,” Ferrari said, describing Notpla’s detergent sachet as a solution to this problem. “Plastic might be cheap currently, but the real cost is much higher in the long term.”

Another area garnering more attention is the refill model. Brands such as Grove Collaborative and Blueland offer refills within the household and laundry space. Grove customers can purchase a glass and silicone dispenser, along with detergent refill pouches made from recycled materials.

While smaller e-commerce brands like Grove continue to grow in the refill sector, the overall landscape remains nascent. The Sustainable Packaging Coalition has said that if more materials are designed to be reusable and refillable then this could change, especially in categories like laundry. According to a report from Precedence Research, the global reusable packaging market is expected to grow rapidly and could be worth nearly $2 billion by 2032.

However, refill models also pose a large responsibility to the consumer. Genco said that many store-based options have failed to gain traction because they are dependent on the consumer remembering to bring their own container. Hewitt added that “they are not widely commercially available at the moment.”

Experts said it’s also paramount that traditional laundry containers end up back in the recycling system. Hewitt said that when consumers properly dispose of laundry packaging it will help protect the environment, and allow brands to produce and sell these materials for a lower cost.

At the same time, there’s also pressure on companies to evolve their approach. Upcoming extended producer responsibility for packaging laws may also play a role in the evolution of laundry packaging. California’s 2022 law is focused specifically on plastics. Broader laws in Colorado, Oregon and Maine could also have an effect.

Speaking broadly, Spiller said the onus is on companies to provide more sustainable solutions that consumers are asking for and major players can lead the way.

“Given the sheer volume and scale of production by CPG companies, it can be difficult for mid-sized and growing organizations to keep up in price,” said Spiller. “It takes years of innovating and iterating until the product eventually levels out to a reasonable price point.”