O-I Glass has released its 2023 sustainability report, touting initiatives around lightweighting, novel processing and production technologies and expanding access to glass recycling.

The climate change strategy for the Ohio-based company, over half of whose business is in beer and wine, addresses furnace tech, energy reduction and efficiency, increasing recycled content and sourcing renewable energy.

Recycling and cullet

O-I listed myriad benefits to increasing the supply of cullet and incorporating more recycled glass into its products. It correlates the use of every 10% of recycled glass in the manufacturing process with a 3% reduction in energy consumption and a 5% reduction in carbon emissions, citing statistics circulated by the European Container Glass Federation. Regarding its ambitions to increase use of recycled content, O-I noted it holds a patent on a bottle made from 100% cullet and has produced it in Europe.

To better secure material, O-I is building out its role in that process; last year it acquired another cullet processing facility, now known as Glass to Glass Denver, to provide nearby plants with nearly 40,000 tons of cullet a year. In 2022 it invested more than $2 million in North America in plant infrastructure, particularly cullet storage. It said it’s also partnering with other industries, such as solar, to turn their end-of-life products into cullet rather than being landfilled.

As for packaging its own products, O-I says it’s trying to reduce the use of plastic film and the weight of fiberboard, and it’s seeking to reuse cardboard and wood pallets where possible. In 2022 O-I began a pilot tracking generated waste, part of a waste sustainability roadmap it implemented.

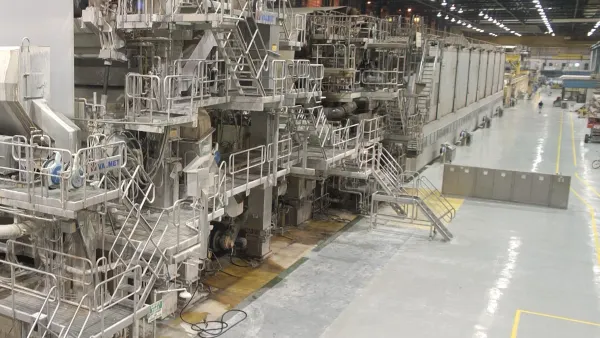

Evolving how glass is made

Over 80% of O-I’s emissions come from fuel consumption and electricity used in the glass-making process.

To improve sustainability at existing sites, O-I plans to transition an average of four furnaces per year through 2030 to gas-oxygen advancement technology, or GOAT. This replaces air with oxygen which the company says results in “a cleaner combustion mix” and requires up to 20% less energy to achieve melt.

As for the future of new facilities, O-I continues to emphasize MAGMA, which stands for modular advanced glass manufacturing asset, as a model for more sustainable glass production. O-I says MAGMA’s smaller physical footprint can be co-located at customer facilities, and its construction is less intensive, too. The company has been piloting MAGMA in the U.S. and abroad in recent years, and it’s central to a facility in Kentucky that O-I broke ground on earlier this year.

Those sites are also poised to incorporate technology that promotes lightweighting, including the use of modeling during the design stage to anticipate potential product issues or to estimate customers’ sustainability benefits. O-I reported that a 2022 pilot of Ultra, its name for this program, resulted in 7.4% lightweighting for a customer.