Companies constantly innovate their packaging to get better performance, improve marketability and enhance sustainability. Here’s a look at some of the recent products and innovations on Packaging Dive’s radar.

Sweet switch

ASR Group brands Domino Sugar and C&H Sugar tubs got makeovers to improve sustainability and user convenience. The previously round tubs are now rectangular, use 28% less plastic and include “instructions on how to recycle.” They can also be refilled using bagged sugar.

Compared with the previous circular tubs, the rectangular design saves space during shipping and in consumers’ homes. ASR says the switch to this design reduces transportation emissions by 65%.

The tubs also increase consumer convenience due to the hinged lid that is attached to the tub, which can be used to level sugar, according to ASR.

Bottoms up

Dutch brand Hoeksche Chips partnered with Atlanta advertising agency Wunderman Thompson to develop “an invention the world didn't know it needed”: a tear-away bottom-left bag corner.

The tearable corner allows the user get every chip crumb into their hand, or directly into their mouth, “without losing your human dignity or, worse, making a mess on your clothes or the couch” by tipping the bag to use the top opening, according to the companies’ news release. The product is now available in the Netherlands.

A-peel-ing trays

Stora Enso introduced Trayforma BarrPeel, a coated paperboard material with a peelable film for vacuum skin packaging. The way the film interacts with the tray’s polymer coating provides a “highly effective barrier” against moisture and oxygen, yet it easily peels away from the recyclable paperboard tray.

The trays are about 90% fiber and less than 10% plastic, “significantly reducing the packaging’s carbon footprint,” according to the company.

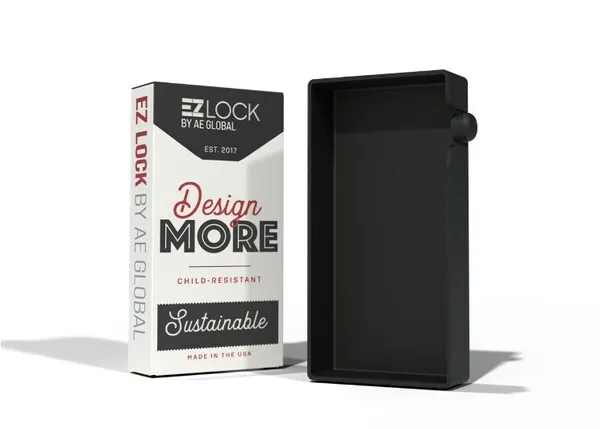

Recovered plastic keeps kids out of cannabis

AE Global released a new version of its EZ Lock custom child-resistant packaging that is made from ocean-bound plastic. The company worked with Ocean Recovery Group to source the plastic, which is sorted, washed and turned into flake. AE Global uses the flake in its injection molding process to create the EZ Lock x ORG packaging. The company says the container has been certified “plastic negative” by rePurpose Global.

“Our closed-loop OBP recovery program captures and converts at-risk materials before it can harm the environment,” AEG Managing Partner Mike Forenza said in a news release.

Recycled PE takes new shapes

Flexible packaging manufacturer Pregis will use Nova Chemicals Corporation’s Syndigo recycled polyethylene resins to make products including stand-up pouches and lay-flat bags. Syndigo is Nova’s first line of mechanically recycled food-safe PE, which it says also offers excellent printability and clarity.