Companies constantly innovate with technology and redesign their packaging to get better performance, improve marketability and enhance sustainability. Here’s a look at four new or updated packaging solutions on Packaging Dive’s radar.

All for one

Laundry detergent brand All will incorporate NaviLens technology on the tubs and pouches for its Free Clear Mighty Packs to aid people with blindness or low vision. The front of the packaging will have scannable codes that connect with the NaviLens app to provide product information in audio form, such as the product’s name, instructions for use and location in a store.

“It is our mission to empower people who are blind or have low vision through our cutting-edge technology,” said NaviLens CEO Javier Pita in a news release. This partnership “marks an important step in offering NaviLens technology in everyday household products, enhancing the shopping experience for all consumers.”

The laundry detergent brand said on its website that it’s making this update to boost equity, because “there is a strong need for accessible resources that assist those with blindness and low vision within everyday environments.”

All said in the release that it is the first laundry detergent in the U.S. to add the NaviLens technology.

No twisting arms

Italian restaurant Carmine’s is also trying to increase accessibility through a partnership with Consumer Convenience Technologies. It’s adding the Eeasy Lid to Carmine’s line of sauces sold in jars at retail stores.

Eeasy Lid aids people with dexterity challenges by allowing customers to vent a vacuum-sealed jar by pressing a button on the top until it clicks. Then the user can twist the lid off. The technology reduces the amount of force needed to open the lid by up to 50%, CCT said in a news release. The lid also can be screwed back onto the jar to preserve any leftover sauce.

The aluminum lid is recyclable, according to CCT. Initially, the accessible jars will be sold in 300 ShopRite stores, with expectations for expansion to other retail locations in the future.

Return to sender

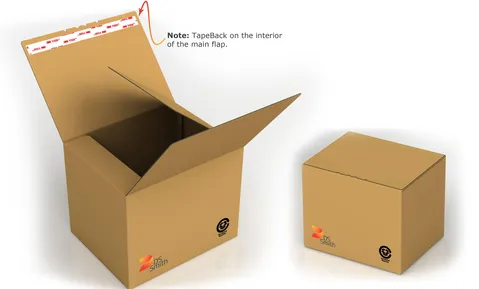

DS Smith introduced a glue strip called Tape Back for e-commerce packaging, designed to let consumers reuse the original packaging to make a return instead of using a new box. The easy-to-peel strip eliminates the need for single-use plastic tear strips and reduces waste, the company said in a news release.

By using one glue strip for two shipments, it allows for the use of less silicon tape, hot melt and corrugated board than competing solutions, according to the company. The solution reduces the amount of hidden non-recyclable materials and avoids mixing components, making a box with Tape Back recyclable at home, DS Smith said.

Pumped up

TriMas Packaging expanded its patented Singolo product line to include an all-plastic pump for foaming products, and the company says it can be recycled.

The pump is made solely from plastic materials — including a polymer-based spring, instead of the traditional metal spring, which aids recycling, TriMas said in a news release. The company says this foaming pump can be used for numerous beauty, personal care and home care applications.

This pump has a similar look, feel and performance as other pumps, and it’s customizable to a variety of sizes, shapes and colors, according to TriMas. It can also accommodate a variety of liquid viscosities.