Companies constantly innovate with new and redesigned packaging to get better performance, improve marketability and enhance sustainability. Here’s a look at six new packaging products that were featured at Pack Expo in Las Vegas this week.

Under the canopy

WestRock and Atlantic Packaging collaborated on a fiber wrap, called Canopy, to replace plastic shrink films on warehouse club-sized packs of food or beverage cans. A WestRock representative said the kraft paper wrap is recyclable in many curbside programs.

Canopy can be retrofitted into existing shrink bundling lines. Machine operators run the paper through the conventional film feed and simply turn off the heat function. Then, Canopy gets tightened and glued around the tray, preventing the cans from falling out.

The WestRock representative demonstrated the product’s strength by showing that a user can pick up the entire pack by the paper wrapper without it wrinkling or tearing. The paper can be printed with brand messaging, just like plastic shrink films.

Reuse over recycling

Orbis showed off the XpressPickup system, a reusable tote and dolly system to support deliveries. The company already offered the dolly base, but now the system is tailored for e-commerce and grocery delivery pickups, in addition to prepared meals deliveries, said Norm Kukuk, president of Orbis. “This system allows for inventory control of all your goods, and for visibility,” he said.

The plastic totes stack when in use and nest when empty for easier storage. The dolly base has a single-touch brake and locking system as well as rounded corners. “The way we designed this is to [prioritize] employee safety and easy mobility,” Kukuk said.

The products are made from HDPE and contain recycled content, which further improves the sustainability profile, Kukuk said. The company’s colored HDPE products can contain up to 20% recycled content, while black parts can contain about 30% to 40%. “The goal, first and foremost, is to reduce the amount of plastic use and drive as much reuse as possible,” he said. “Recycling is a last resort.”

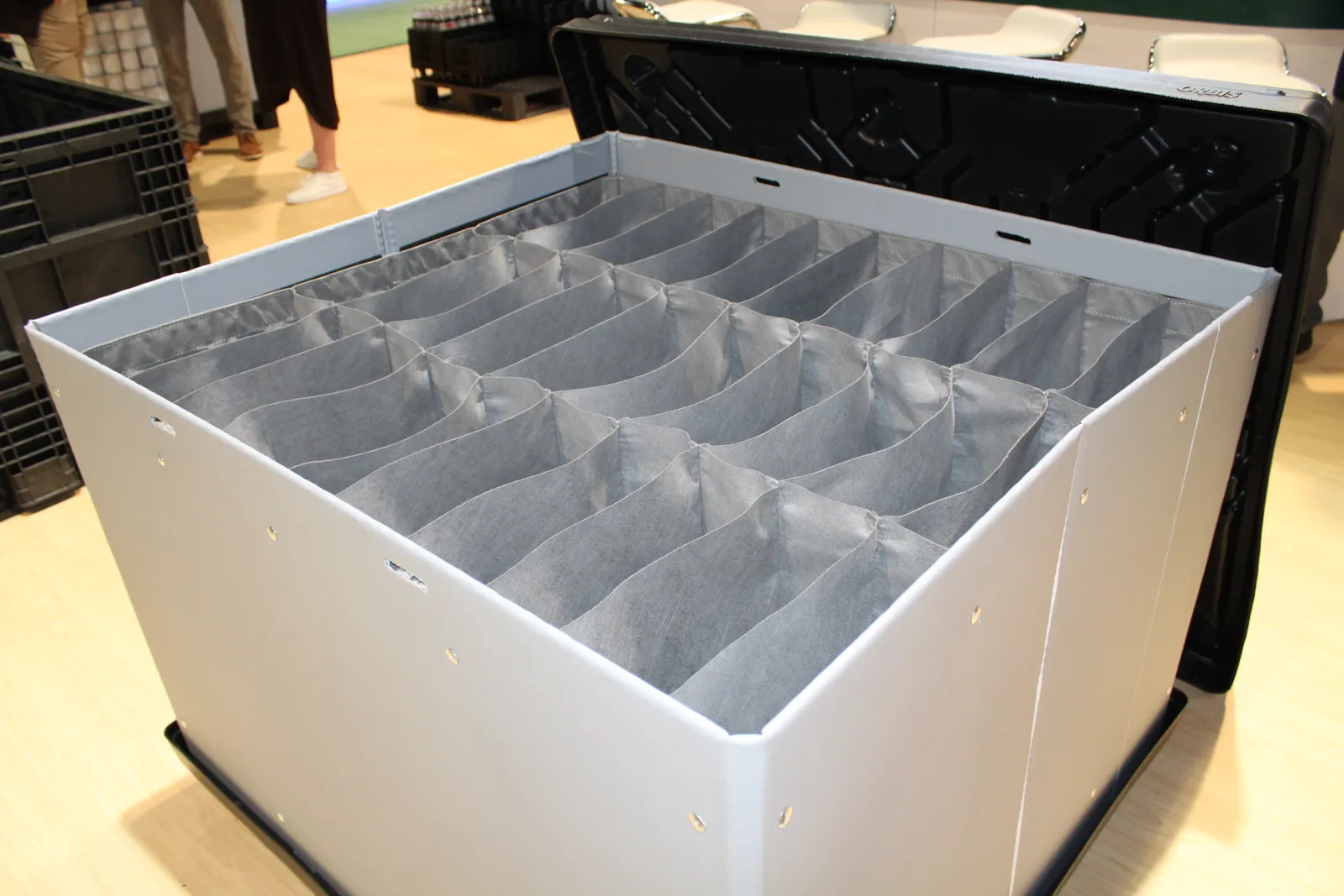

Orbis also featured its reusable OpteBulk container system, comprised of a plastic pallet, sleeve, internal textile separators and a top cap. It’s meant to help customers’ logistics efficiency on returns, Kukuk said.

The sleeve is collapsible for easy storage and, like the XpressPickup system, has rounded corners for safety. The closed, rounded edges are a key feature for the sleeve, Kukuk said, considering many competing products have open, corrugated edges that can scratch or cut users.

The lightweight polypropylene sleeve components can be switched to polyethylene for non-food-grade applications, Kukuk said. The pallet base and top are HDPE and contain recycled content. “We use a lot of recycled content to keep plastic in use in reusable packaging,” he said.

Go with the flow

Flow Beverage Corp. is the first brand to use Tetra Pak’s new premium ink jet printing service on fiber cartons; Tetra Pak says it is the first and only company to offer this solution. Pedro Gonçalves, Tetra Pak U.S. and Canada marketing director, said the digitally-enabled printing capabilities allow flexibility in customer designs, which helps their marketing campaigns.

“We can do multiple colors or designs in one case,” he said. “Customers can launch impactful campaigns that offer the potential for greater consumer interest and engagement.” The individual cartons’ different designs can be printed to show a unified message when lined up next to each other and positioned a certain way, and a drop of glue can keep them in place to prevent the products from turning and altering the message.

Ink jet printing also “really increases sustainability” and efficiency compared to conventional carton printing options, such as flexography, which require costly, lengthy change-out processes for printing plates and inks, Gonçalves said. “This is like ink jet printing at home but on a much larger scale.”

The Flow cartons soon will roll out at LiveNation concert venues, starting in Canada.

Fancy plants

After three years of development, RyPax and CelluComp introduced what they call an “industry first” biodegradable all-fiber bottle made from plant-based materials. The novel fiber bottle is made from what the partners say are “highly renewable feedstock” components: a combination of CelluComp’s proprietary Curran, developed from cellulose fibers in root vegetables, such as sugar beets; bagasse, a sugar cane waste; and bamboo. The fiber has “minimal porosity” and the bottle has a thin, fiber-based coating, eliminating the need for plastic liners.

The partners are ready to scale the product to mass production for a variety of applications, including food, beverages, beauty, health and medicine. They’re working on other fiber-based packaging solutions including caps and screw threads.

Seal again and again

Terphane introduced Resealphane, a resealable version of the plastic film Sealphane that it introduced in 2005. The company said in a launch video that the “easy open, easy close” product simplifies the experience for consumers.

The polyester film can be closed multiple times, is tamper evident, has high transparency and can have an anti-fog option that accepts printing, according to Terphane. The film also can be completely removed from the base package, a feature the company said many competing products do not offer.

The company says Resealphane uses 30% less plastic than clamshells, and it is thinner than other films, which it says makes it a more sustainable option. It can also be added to existing packaging lines, reducing the need for new investment.